My last days holiday, we have a use it or lose it policy at works so I needed to use up my final day be for the end of the month, plus I needed to wind down after the stress of yesterday’s ISO accreditation audit. The first job of the day was to finish trimming the flooring.

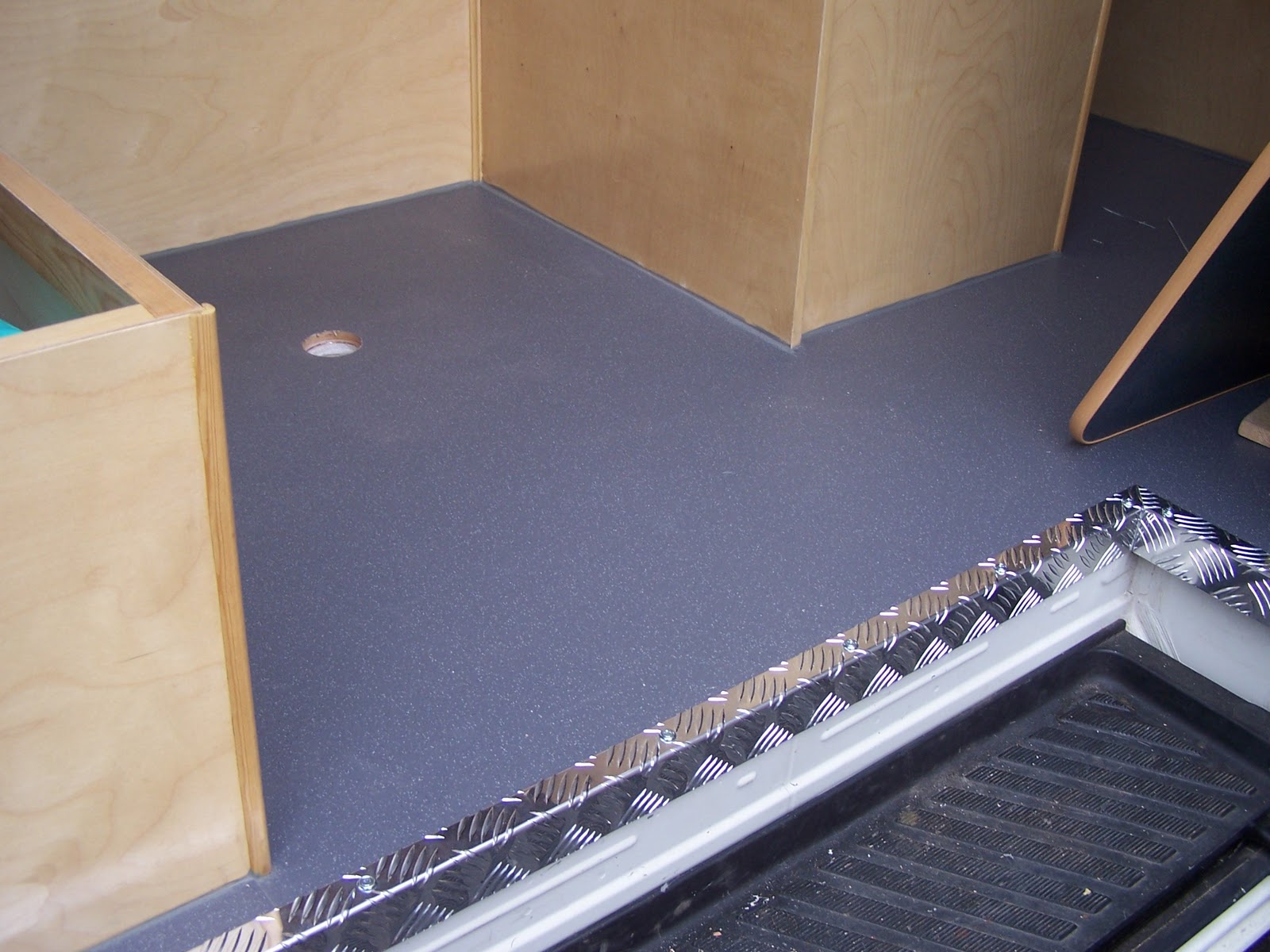

Rather than attemping to make the flooring an exact fit, I cut it slightly smaller leaving a 2-3mm gap all the way around the edge. Trimming done, I lifted the flooring, put to down double sided vinyl flooring tape around the edge of the floor and inset by 10mm, then relaid the floor. The next step was to use the grey sealant fill the gap arround the edge of the flooring to give a water tight seal, and finally to cap the edge of the step with the angled chequer plate.

The greater part of the afternoon was spent routing out an 18mm thick disk for the table base to fit in. The table base needs a 50mm thick floor but my floor is only about 40mm thick. Anyway having produced my spacer, even going as far as routing an ogee edge, we sited the table and I cut the hole in the floor. As luck would have it although I only just missed the central groove in the floor, I did hit the step going down so rather than needing in my 18mm pad I only needed a piece 3mm thick. Thus it was that I ditched my afternoons work and quickly routed a giant washer out of my 3mm ply.

The evening was then spent applying coats of varnish to the ply at regular intervals